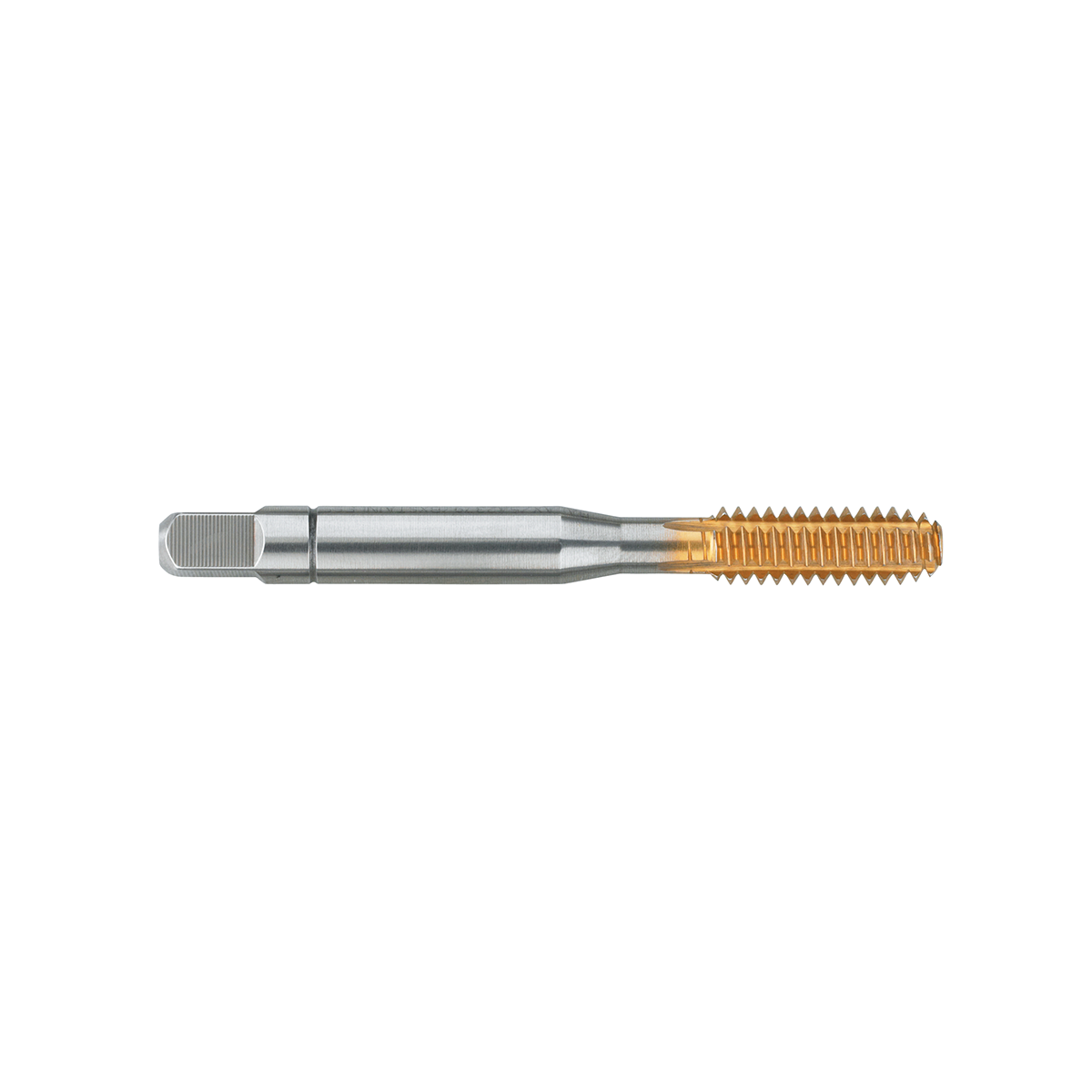

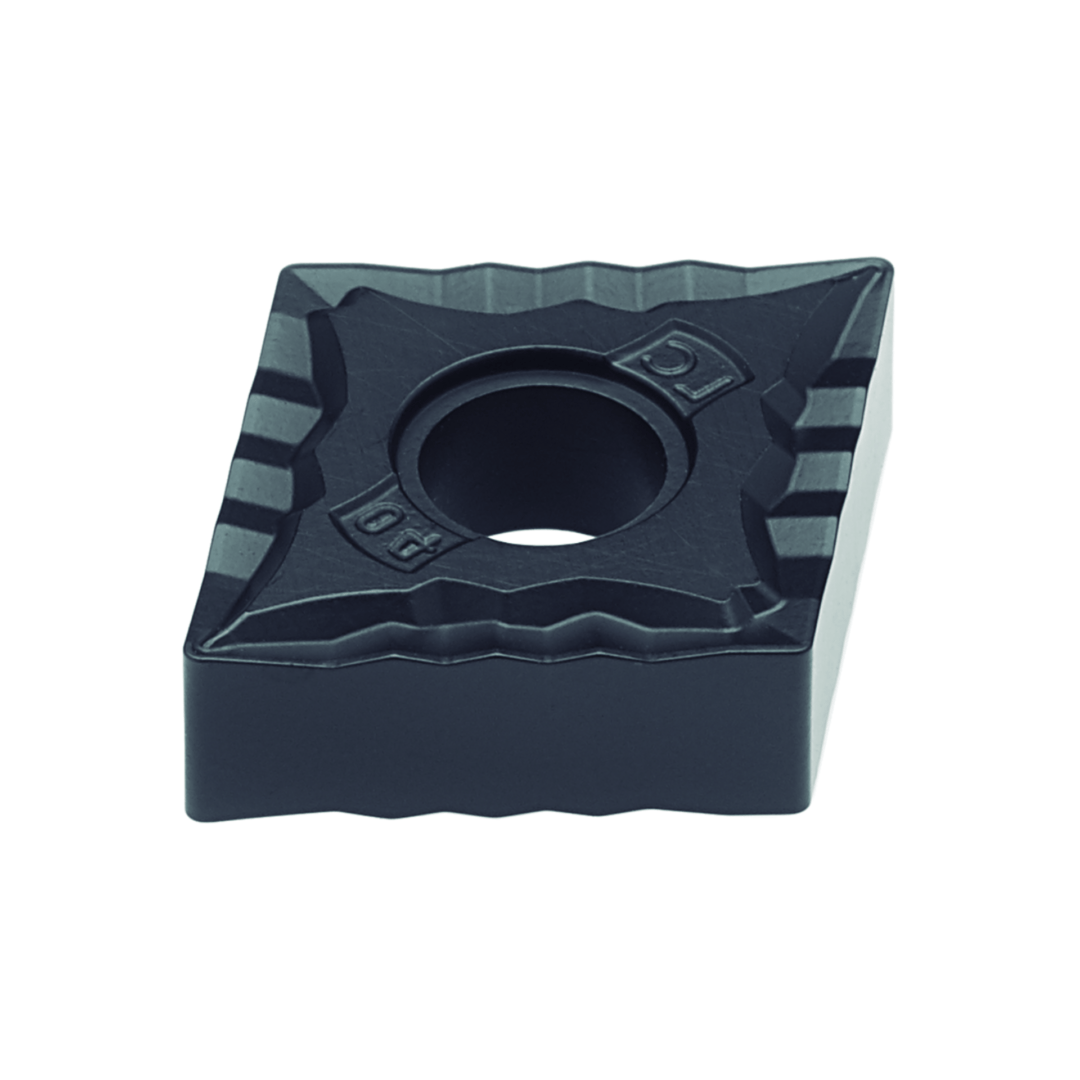

Series BXS

Additional information

| Brand | GWS Tool Group |

|---|---|

| Series | BXS |

The HSS Taps Series BXS is a specialized line of high-speed steel (HSS) taps designed for exceptional performance in a wide range of threading applications. Engineered with precision and durability in mind, these taps are ideal for use in industries such as automotive, aerospace, and general manufacturing.

Manufactured from premium high-speed steel, the BXS series taps exhibit excellent wear resistance and toughness, ensuring reliable performance even under rigorous conditions. The taps are available in various flute designs, including straight and spiral flutes. Spiral flutes are particularly effective for blind hole applications, as they facilitate efficient chip evacuation, reducing the risk of clogging and ensuring clean, precise threads.

The BXS series offers a comprehensive selection of sizes and pitch configurations, meeting both standard and fine threading requirements. This versatility makes them suitable for threading a variety of materials, including aluminum, mild steel, and stainless steel. The range includes taper taps for starting threads, plug taps for through holes, and bottoming taps for finishing threads in blind holes.

To further enhance performance, the BXS taps can be coated with advanced materials such as Titanium Nitride (TiN), Titanium Carbonitride (TiCN), or Titanium Aluminum Nitride (TiAlN). These coatings reduce friction, increase surface hardness, and extend tool life, resulting in higher-quality threads and reduced tool wear.

Overall, the HSS Taps Series BXS provides a robust and versatile solution for precision threading tasks, combining high-quality construction, efficient chip management, and adaptability across various applications.

Part | Thread Size | Classification | Chamfer | Thread Limit | Min Tap/Drill Size | Max Tap/Drill Size | Shank (C) | Square Size (D) | OAL (L) |

|---|---|---|---|---|---|---|---|---|---|

4-40 | UNC | 1.5 | H5 | 0.100 | 0.103 | .141 | .110 | 1-7/8 |

|

4-40 | UNC | 2.5 | H5 | 0.100 | 0.103 | .141 | .110 | 1-7/8 |

|

6-32 | UNC | 1.5 | H5 | 0.123 | 0.126 | .141 | .110 | 2 |

|

6-32 | UNC | 2.5 | H5 | 0.123 | 0.126 | .141 | .110 | 2 |

|

8-32 | UNC | 1.5 | H5 | 0.149 | 0.152 | .168 | .131 | 2-1/8 |

|

8-32 | UNC | 2.5 | H5 | 0.149 | 0.152 | .168 | .131 | 2-1/8 |

|

10-24 | UNC | 1.5 | H5 | 0.169 | 0.173 | .194 | .152 | 2-3/8 |

|

10-24 | UNC | 2.5 | H5 | 0.169 | 0.173 | .194 | .152 | 2-3/8 |

|

10-32 | UNF | 1.5 | H5 | 0.175 | 0.178 | .194 | .152 | 2-3/8 |

|

10-32 | UNF | 2.5 | H5 | 0.175 | 0.178 | .194 | .152 | 2-3/8 |

|

1/4-20 | UNC | 1.5 | H8 | 0.226 | 0.231 | .255 | .191 | 2-1/2 |

|

1/4-20 | UNC | 2.5 | H8 | 0.226 | 0.231 | .255 | .191 | 2-1/2 |

|

1/4-28 | UNF | 1.5 | H7 | 0.233 | 0.237 | .255 | .191 | 2-1/2 |

|

1/4-28 | UNF | 2.5 | H7 | 0.233 | 0.237 | .255 | .191 | 2-1/2 |

|

5/16-18 | UNC | 1.5 | H9 | 0.285 | 0.291 | .318 | .238 | 2-23/32 |

|

5/16-18 | UNC | 2.5 | H9 | 0.285 | 0.291 | .318 | .238 | 2-23/32 |

|

5/16-24 | UNF | 1.5 | H8 | 0.293 | 0.297 | .318 | .238 | 2-23/32 |

|

5/16-24 | UNF | 2.5 | H8 | 0.293 | 0.297 | .318 | .238 | 2-23/32 |

|

3/8-16 | UNC | 1.5 | H9 | 0.344 | 0.350 | .381 | .286 | 2-15/16 |

|

3/8-16 | UNC | 2.5 | H9 | 0.344 | 0.350 | .381 | .286 | 2-15/16 |

|

3/8-24 | UNF | 1.5 | H8 | 0.355 | 0.359 | .381 | .286 | 2-15/16 |

|

3/8-24 | UNF | 2.5 | H8 | 0.355 | 0.359 | .381 | .286 | 2-15/16 |

|

7/16-14 | UNC | 2.5 | H9 | 0.401 | 0.408 | .323 | .242 | 3-5/32 |

|

7/16-20 | UNF | 2.5 | H7 | 0.413 | 0.418 | .323 | .242 | 3-5/32 |

|

1/2-13 | UNC | 2.5 | H9 | 0.461 | 0.468 | .367 | .275 | 3-3/8 |

|

1/2-20 | UNF | 2.5 | H7 | 0.475 | 0.480 | .367 | .275 | 3-3/8 |

|

M3 x 0.5 | M | 1.5 | D6 | 0.110 | 0.112 | .141 | .110 | - |

|

M3 x 0.5 | M | 2.5 | D6 | 0.110 | 0.112 | .141 | .110 | - |

|

M3.5 x 0.6 | M | 1.5 | D7 | 0.128 | 0.130 | .141 | .110 | - |

|

M3.5 x 0.6 | M | 2.5 | D7 | 0.128 | 0.130 | .141 | .110 | - |

|

M4 x 0.7 | M | 1.5 | D7 | 0.145 | 0.148 | .168 | .131 | - |

|

M4 x 0.7 | M | 2.5 | D7 | 0.145 | 0.148 | .168 | .131 | - |

|

M5 x 0.8 | M | 1.5 | D8 | 0.183 | 0.186 | .194 | .152 | - |

|

M5 x 0.8 | M | 2.5 | D8 | 0.183 | 0.186 | .194 | .152 | - |

|

M6 x 1.0 | M | 1.5 | D9 | 0.218 | 0.222 | .255 | .191 | - |

|

M6 x 1.0 | M | 2.5 | D9 | 0.218 | 0.222 | .255 | .191 | - |

|

M8 x 1.25 | M | 1.5 | D10 | 0.292 | 0.297 | .318 | .238 | - |

|

M8 x 1.25 | M | 2.5 | D10 | 0.292 | 0.297 | .318 | .238 | - |

|

M10 x 1.5 | M | 1.5 | D11 | 0.366 | 0.372 | .381 | .286 | - |

|

M10 x 1.5 | M | 2.5 | D11 | 0.366 | 0.372 | .381 | .286 | - |

|

M12 x 1.75 | M | 1.5 | D12 | 0.439 | 0.446 | .367 | .275 | - |

|

M12 x 1.75 | M | 2.5 | D12 | 0.439 | 0.446 | .367 | .275 | - |