Series BX170

Additional information

| Brand | GWS Tool Group |

|---|---|

| Series | BX170 |

The HSS Taps Series BX170 is an advanced line of high-speed steel taps, meticulously designed for high-precision threading in both metric and imperial measurements. These taps are particularly well-suited for threading applications in a variety of materials, including aluminum, mild steel, and stainless steel, making them indispensable in industries such as automotive, aerospace, and general engineering.

Crafted from superior high-speed steel, the Series BX170 taps exhibit excellent wear resistance and longevity, maintaining their cutting edge even during prolonged use. The taps are engineered with features like straight flutes for general-purpose threading and spiral flutes that efficiently evacuate chips, which is crucial for preventing clogging in blind hole applications.

The Series BX170 taps come in a diverse range of sizes and pitch configurations, ensuring they can meet specific threading needs with precision. The series includes taper taps for easy thread starting, plug taps for general threading tasks, and bottoming taps for completing threads to the bottom of blind holes, providing comprehensive solutions for various threading requirements.

To further enhance their performance, especially when working with harder materials, the Series BX170 taps can be coated with advanced coatings such as Titanium Nitride (TiN), Titanium Carbonitride (TiCN), or Titanium Aluminum Nitride (TiAlN). These coatings significantly reduce friction, increase surface hardness, and extend the lifespan of the taps, resulting in superior thread quality and operational efficiency.

With their blend of precision, durability, and versatility, the HSS Taps Series BX170 stands out as a reliable choice for professionals who demand high-quality threading tools for a wide array of applications.

Part | Thread Size | Classification | Thread Limit | Flutes | Shank (C) | Square Size (D) | OAL (L) | Coating |

|---|---|---|---|---|---|---|---|---|

4-40 | UNC | H2 | 3 | .141 | .110 | 4 | TiN |

|

6-32 | UNC | H3 | 3 | .141 | .110 | 4 | TiN |

|

8-32 | UNC | H3 | 3 | .168 | .131 | 4 | TiCN |

|

10-24 | UNC | H3 | 3 | .194 | .152 | 6 | TiCN |

|

10-24 | UNC | H3 | 3 | .194 | .152 | 6 | TiN |

|

10-32 | UNF | H3 | 3 | .194 | .152 | 6 | TiCN |

|

10-32 | UNF | H3 | 3 | .194 | .152 | 6 | TiN |

|

1/4-20 | UNC | H5 | 3 | .255 | .191 | 6 | TiN |

|

5/16-18 | UNC | H5 | 3 | .318 | .238 | 6 | TiCN |

|

5/16-18 | UNC | H5 | 3 | .318 | .238 | 6 | TiN |

|

5/16-24 | UNF | H4 | 3 | .318 | .238 | 6 | TiCN |

|

5/16-24 | UNF | H4 | 3 | .318 | .238 | 6 | TiN |

|

3/8-16 | UNC | H5 | 3 | .381 | .286 | 6 | TiN |

|

3/8-24 | UNF | H4 | 3 | .381 | .286 | 6 | Bright |

|

3/8-24 | UNF | H4 | 3 | .381 | .286 | 6 | TiCN |

|

M3 x 0.5 | M | D3 | 3 | .141 | .110 | 4 | TiCN |

|

M3 x 0.5 | M | D3 | 3 | .141 | .110 | 4 | TiN |

|

M4 x 0.7 | M | D4 | 3 | .168 | .131 | 4 | TiCN |

|

M4 x 0.7 | M | D4 | 3 | .168 | .131 | 4 | TiN |

|

M5 x 0.8 | M | D4 | 3 | .194 | .152 | 6 | TiCN |

|

M5 x 0.8 | M | D4 | 3 | .194 | .152 | 6 | TiN |

|

M6 x 1.0 | M | D5 | 3 | .255 | .191 | 6 | TiCN |

|

M6 x 1.0 | M | D5 | 3 | .255 | .191 | 6 | TiN |

|

M8 x 1.25 | M | D5 | 3 | .318 | .238 | 6 | TiN |

|

M10 x 1.5 | M | D6 | 3 | .381 | .286 | 6 | TiCN |

|

M10 x 1.5 | M | D6 | 3 | .381 | .286 | 6 | TiN |

|

M8 x 1.25 | M | D5 | 3 | .318 | .238 | 6 | TiCN |

|

1/4-28 | UNF | H4 | 3 | .255 | .191 | 6 | TiCN |

|

3/8-16 | UNC | H5 | 3 | .381 | .286 | 6 | TiCN |

|

M8 x 1.25 | M | D5 | 3 | .318 | .238 | 6 | Bright |

|

1/4-20 | UNC | H5 | 3 | .255 | .191 | 6 | TiCN |

|

M3.5 x 0.6 | M | D4 | 3 | .141 | .110 | 4 | Bright |

|

1/4-20 | UNC | H5 | 3 | .255 | .191 | 6 | Bright |

|

5/16-24 | UNF | H4 | 3 | .318 | .238 | 6 | Bright |

|

M3 x 0.5 | M | D3 | 3 | .141 | .110 | 4 | Bright |

|

3/8-16 | UNC | H5 | 3 | .381 | .286 | 6 | Bright |

|

10-32 | UNF | H3 | 3 | .194 | .152 | 6 | Bright |

|

M10 x 1.5 | M | D6 | 3 | .381 | .286 | 6 | Bright |

|

6-32 | UNC | H3 | 3 | .141 | .110 | 4 | Bright |

|

8-32 | UNC | H3 | 3 | .168 | .131 | 4 | Bright |

|

M6 x 1.0 | M | D5 | 3 | .255 | .191 | 6 | Bright |

|

1/4-28 | UNF | H4 | 3 | .255 | .191 | 6 | Bright |

|

5/16-18 | UNC | H5 | 3 | .318 | .238 | 6 | Bright |

|

M5 x 0.8 | M | D4 | 3 | .194 | .152 | 6 | Bright |

|

4-40 | UNC | H2 | 3 | .141 | .110 | 4 | Bright |

|

M4 x 0.7 | M | D4 | 3 | .168 | .131 | 4 | Bright |

|

10-24 | UNC | H3 | 3 | .194 | .152 | 6 | Bright |

Related products

Related products

-

Shoulder End Mill Cutter PLUS AN90-12 D1.25-W1.25/6.50-03-12

Read more -

Insert VNMG 160408-MS PH0910

Read more -

1/8″ SelectMill 3-Flute Aluminum Uncoated

Read more -

Shoulder End Mill Cutter PLUS AN90-12 D1.00-W1.00/6.00-02-12

Read more -

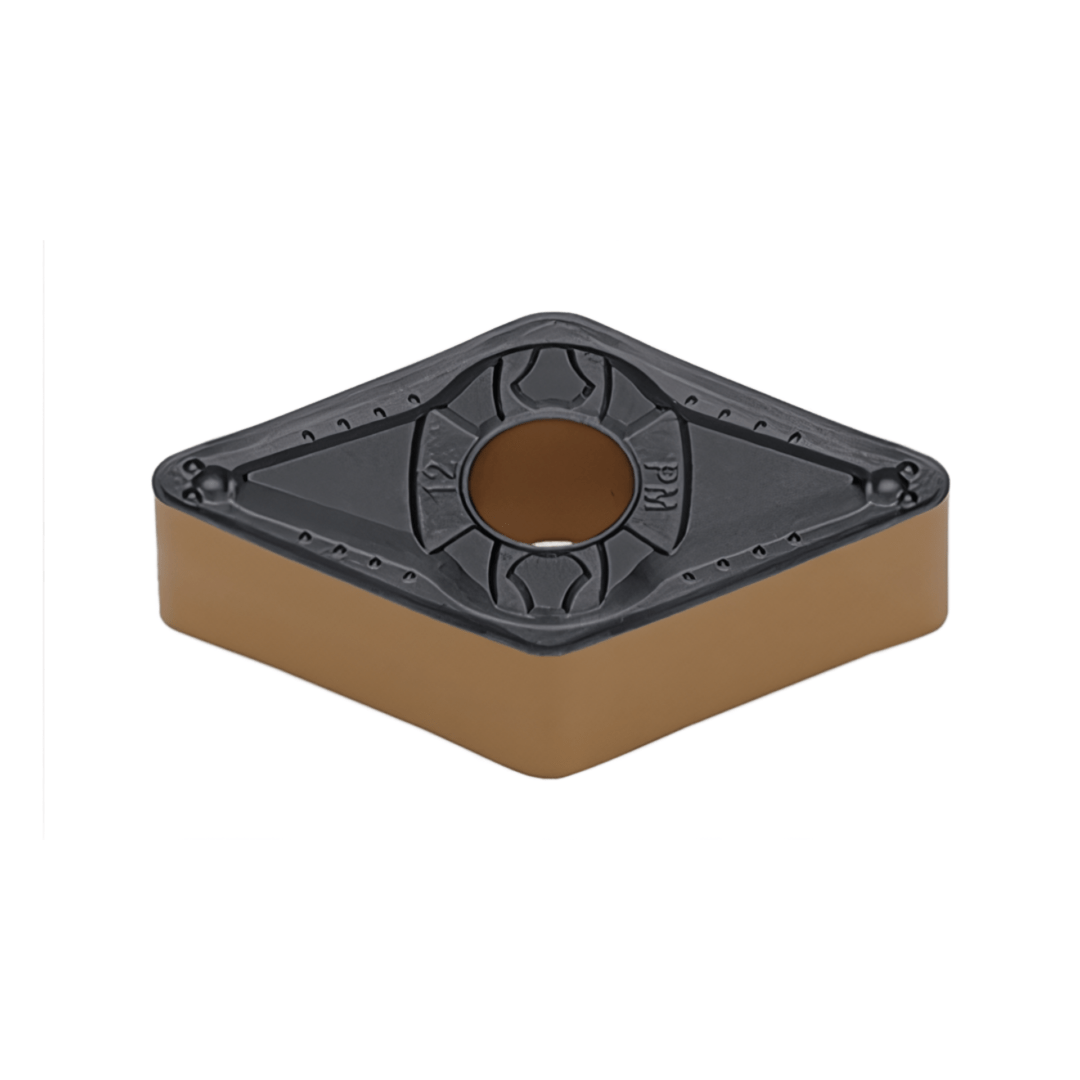

Insert DNMG 150608-PM PHG125

Read more -

Shoulder End Mill Cutter PLUS AN90-10 D.750-W.750/3.94-02-10*

Read more